Optimize QC Accuracy and Efficiency

Key to achieving the precision-measurement results you need is an expert understanding of the measuring equipment in use—not just during, but prior to, inspection, when programming the instruments to the part application is critical.

Touchstone Measurement applies decades of experience in dimensional inspection to write CMM programs for a wide range of testing and QC procedures. Touchstone is a dedicated resource that can deliver these programs in a timely and cost-efficient manner. With Touchstone, delivery is much faster than what clients can do on their own.

Anatomy of a CMM

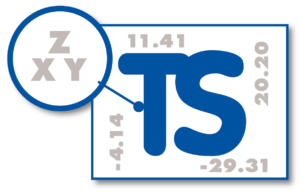

A CMM or Coordinate Measuring Machine is a computerized mechanical system designed to move a measuring stylus or probe to establish a set of coordinate points on a part’s surface.

A CMM’s complete measuring system has four integrated functional components:

- The measuring machine

- The measuring probe

- The control/computing system

- The measuring software

CMMs might involve programming the measuring probe to touch predetermined points along the inspected part, where it records the X, Y and Z coordinates for each point relative to a benchmark reading. Other CMM probes move along the surface of the part to take measurements at specified intervals.

CMM Insights:

1. CMM Functions

Touchstone is available to perform a variety of measuring and testing functions. Some common applications for CMMs include:

- Dimensional measurement

- Profile measurement

- Orientation (angularity)

- Depth mapping

- Digitizing/imaging

- Shaft measurement

2. Standard CMM Features

Using the latest CMM equipment, Touchstone technicians can perform:

- Offline Programming

- Reverse Engineering

- Statistical Process Control (SPC) software

- Automatic temperature compensation

- Shop-friendly floor footprint

3. CMM Software Programs

Touchstone currently offers two CMM software programs